Adidas to Introduce PRIMEBLUE and PRIMEGREEN Sustainable Tech

Manila, Philippines– Adidas aims to end plastic waste through new sustainable technologies and key partnerships.

As one of the world’s largest shoe manufacturers, Adidas admits its a big contributor to the global plastic problem. For this reason, the brand made a commitment to END PLASTIC WASTE.

For every person on the planet, there is one ton of plastic and nearly 80 percent has become plastic waste wreaking havoc on the oceans around the world.

At the core of its new solutions are the PRIMEBLUE and PRIMEGREEN. Both are sustainable technologies that use recycled plastic.

“We’re not just focused on changing how we do business; we’re dedicated to changing how our industry does business, ” said James Carnes, Adidas’ Vice President of Brand Strategy .

Since 2012, adidas has innovated new products and processes with sustainability focused partners like Parley for the Oceans, Stella McCartney and the U.S. International Space Station. After introducing a single shoe at the United Nations in 2015, the long-term eco-innovation partnership with Parley for the Oceans that will lead to more than 15 million pairs of shoes being produced with Parley Ocean Plastic®. This year will also mark the launch of PRIMEBLUE and PRIMEGREEN performance fabrics, two new sustainable technologies where 100% of the polyester used is recycled.

PRIMEBLUE, a performance fabric which contains Parley Ocean Plastic®, is now included in some of the brand’s most iconic and visible performance products like Ultraboost 20 and in the uniforms of some of the biggest leagues and teams in the world.

PRIMEGREEN, a performance fabric which contains no virgin plastic, will be available later this year and will also be featured in key competitive products. Both performance fabrics will play a significant role in adidas reaching more than 50% total volume of recycled polyester at the end of 2020 and its commitment to END PLASTIC WASTE.

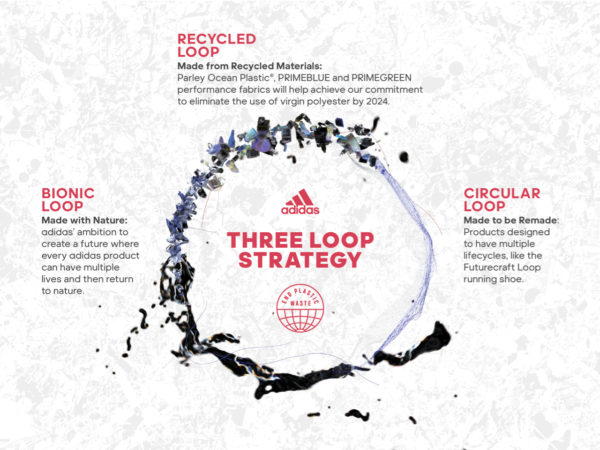

adidas’ commitment comes to life through a Three Loop Strategy, which focuses the brand’s efforts on creating three categories of sustainable products:

- Recycled Loop – Made from Recycled Materials: Supported by the introduction of PRIMEBLUE and PRIMEGREEN performance fabrics.

- Circular Loop – Made to be Remade: Products whose life cycles continue after each use, like the Futurecraft Loop running shoe.

- Bionic Loop – Made with Nature: adidas’ ambition to create a future where every adidas product can have multiple lives and then return to nature.

As the original sports brand, adidas continues to create only the best products for its athletes, and these sustainable products are no exception. All of these more sustainable products will meet or exceed all of adidas’ elite performance standards.

In the next decade the brand is committed to doing even more to END PLASTIC WASTE.

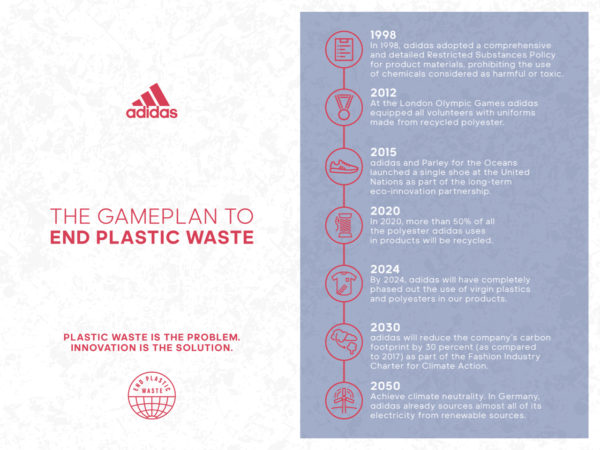

- 2020: more than 50% of all the polyester adidas uses in products will be recycled

- 2021: adidas will work with adidas’ key US sports partners (MLS, NHL, USA Volleyball and the Power 5 NCAA football programs) to transition to more sustainable uniforms.

- 2024: adidas will use only recycled polyester in all adidas products across the business – aided by the introduction of PRIMEBLUE and PRIMEGREEN performance fabrics where 100% of the polyester used is recycled.

- 2030: adidas will reduce the company’s carbon footprint by 30 percent (as compared to 2017) as part of the Fashion Industry Charter for Climate Action.

- 2050: achieve climate neutrality. In Germany, the company already sources almost all its electricity from renewable sources.

“We believe that through sport we have the power to change lives, and we are dedicated to creating that change. Since 1998, we’ve been developing and introducing innovations to END PLASTIC WASTE. Our commitment to eliminate the use of virgin polyester in our products by 2024 helps us get one step closer to being a more circular company,” James Carnes, VP Brand Strategy said.

Adidas’ products and processes will be a part of a new circular business model that includes extending the life of a product through rental, repair or re-commerce, being remade into new products and then ultimately returning to nature. Using materials that can be recycled multiple times, developed from natural resources or made from cells and proteins in a lab.

For more information, visit https://www.adidas.com.ph/ or Instagram via https://www.instagram.com/adidasph/.